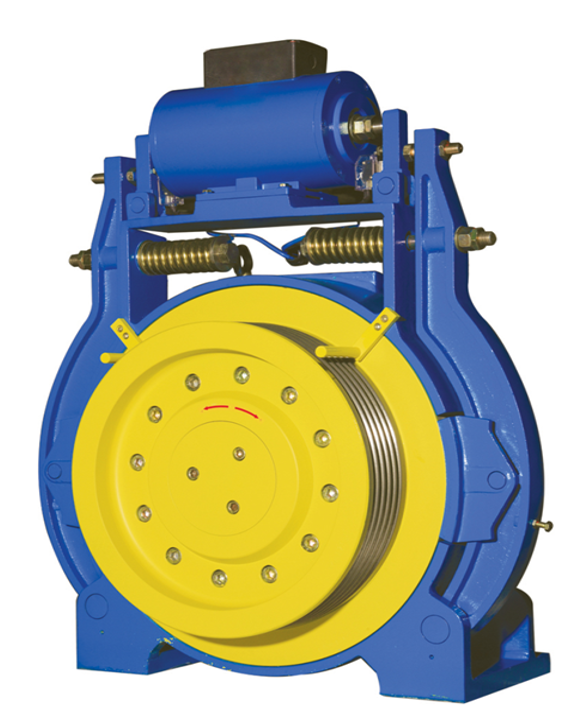

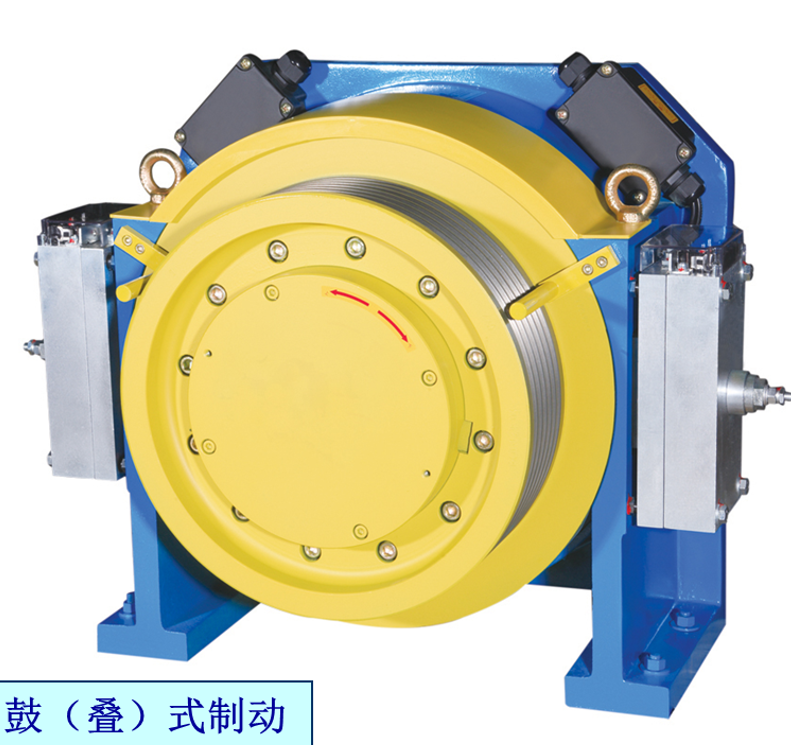

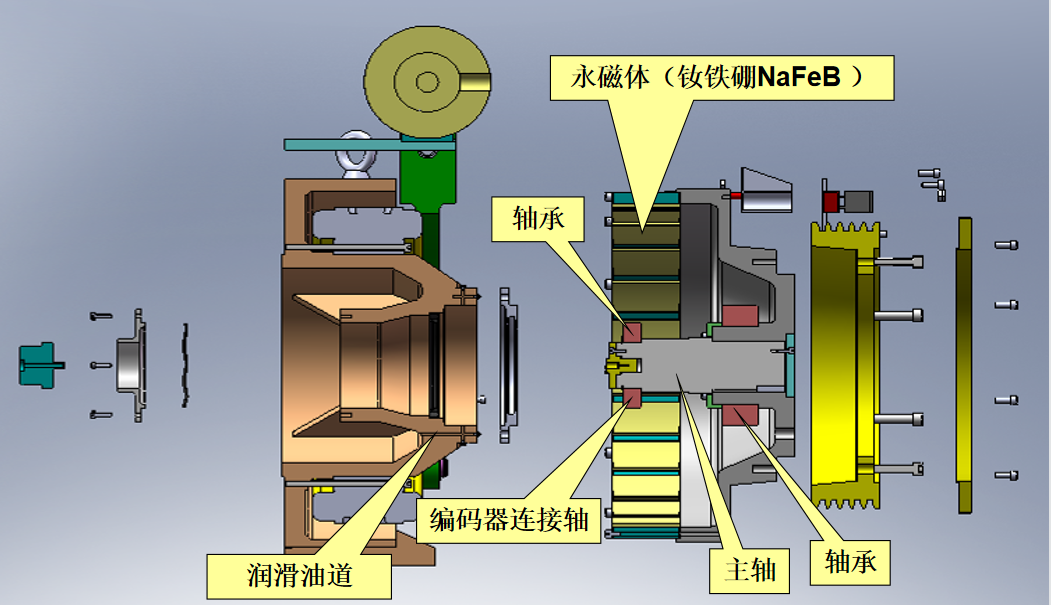

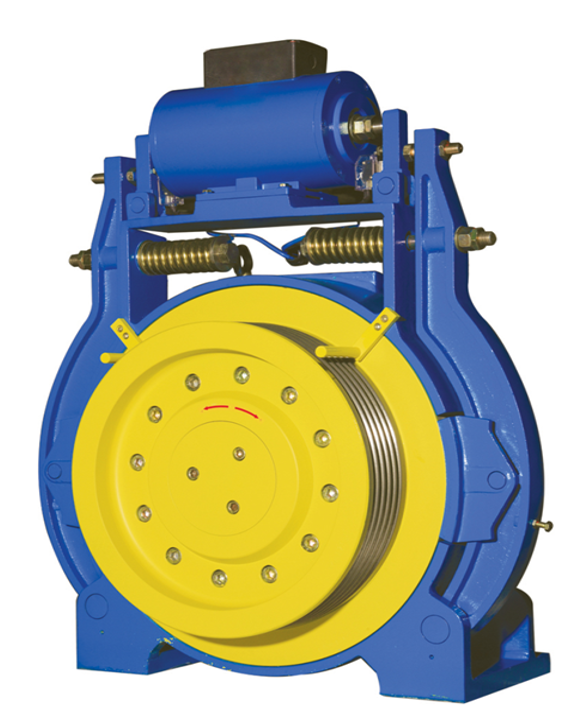

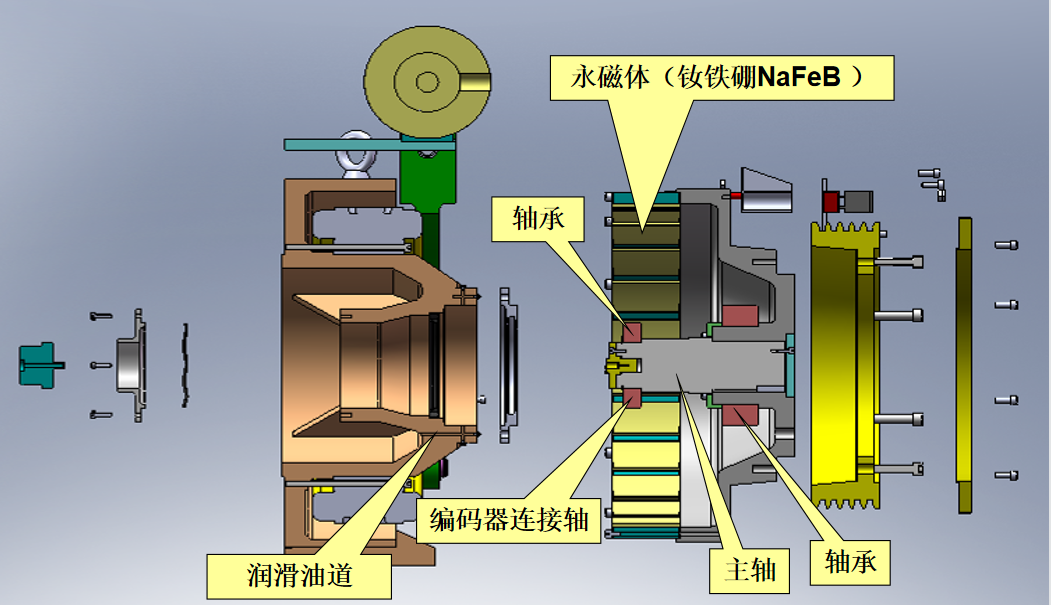

1. simple structure, no need for a gearbox, simpler process, while reducing the volume and weight, improving the utilisation of effective space.

2. low vibration and noise, especially in the low speed operation area, the advantages are more obvious, stable operation and high speed regulation accuracy. Most of the noise of traditional gear traction lifts comes from the mechanical vibration generated by the gearbox and the vibration and noise of the high-speed rotating motor itself. The gearless traction machine does not use a gearbox and the rated speed of the motor is very low, so the vibration and noise of the motor itself is very small, thus the noise of the whole lift system is greatly reduced.

3. Since gearless speed regulation is achieved, there is no secondary deceleration process, which eliminates the loss of the gearbox and improves efficiency. At the same time, the use of permanent magnet excitation, no excitation current, no excitation loss, can also make the efficiency increased.

4, high power factor. The power factor can be as high as 0.9 or more.

5. Safe, reliable and comfortable. The use of permanent magnet synchronous motor drive can effectively stop the phenomenon of lift slippage. At the same time, the motor can provide sufficient torque at low frequency, low pressure and low speed to avoid jittering during the slow start of the lift and improve the comfort of the lift starting and braking process.

6、Machine room-less lifts with various traction methods can be arranged, showing high freedom and flexibility even when there are machine rooms and small machine rooms arranged.